Reflections: Robert E. Parks

Frequently, when I first interview someone for their Reflections bio, I ask if they have a favorite quote. I find that asking someone their favorite quote is a great way to get to know them better and learn what has encouraged and empowered them over the years. While Research Professor Robert (Bob) E. Parks does not have a favorite quote, he does have a simple motto he has found to be true throughout his career in optics, “Wisdom is realizing the obvious.”

Early Life

Born 22 January 1942 to Helen Edson and James Parks, Bob spent the first two years of his life in Lakewood, Ohio, before his family moved to Erie, Pennsylvania, in 1944 and welcomed his brother Boyd in 1946. Both of Bob’s parents were college graduates, graduating with bachelor’s degrees during the Depression—his mother from Ohio Wesleyan University in Delaware, Ohio, and his father from Rollins College in Winter Park, Florida.

In 1952, after Bob’s parents separated, his mother moved with Bob and Boyd back to Cleveland, Ohio, to live with their grandfather. By this time, his grandfather was a widower and soon moved to Florida to “avoid the chaos of two young boys.”

At an early age, my brother and I learned to shop and cook while our mother was out making a living. When we objected, she said, ‘if we didn’t cook dinner then she guessed we wouldn’t eat that night.’ That always got us back on track.

Education

History, as well as Bob’s college plans, changed on 4 October 1957 when the Soviet Union successfully launched Sputnik. As a sophomore in high school, Bob began to look at engineering schools—a choice led by a sense of heightened patriotism at the time.

I would have chosen English or history as majors, but was also good in math and science, so I started looking at engineering schools. Wanting to go somewhere where humanities were also important, I decided to major in physics at Ohio Wesleyan University (OWU)—under their 3-2 program—and finishing up at somewhere like MIT where I had been accepted, but with no scholarship. This plan was affordable as I was a legacy at OWU and was relatively close to my home in Cleveland.

Once at OWU, the head of the Physics Department convinced Bob to finish his BA at OWU, then pursue a MA at another school. Bob’s common interest in science and humanities led him to Williams College in Williamstown, Massachusetts, where there was a small master’s program in physics and an advisor who was interested in the history of science. Perfect, except …

On arriving at Williams College, I was informed the professor I wanted as my advisor was retiring in a year and I was assigned to Professor Fielding Brown. I explained to Dr. Brown my interest in the history of science; he listened patiently then replied, ‘That’s nice but I am doing research with a ruby laser.’ He then asked me if I could ‘align end-mirrors on a laser cavity using an autocollimator.’ As I was familiar with the idea, I said, ‘yes,’ and thus began my career path in optics.

Bob has always considered this change in advisor to be a “stroke of luck,” as his work with professor Brown on plasmon interactions with light ignited his excitement in quantum optics, which led him to be admitted to the PhD program in Physics at the University of Rochester (UR) in Rochester, New York. It was at UR that he met Jim Wyant in a math-physics class in the fall of 1966.

Early Career

Realizing that he was much more of an experimentalist than a theorist, Bob decided to drop out of the physics program at UR after the first semester.

This was in the middle of the Vietnam War, and at this point I had to find a job or walk to the Draft Board. The obvious choice for a job in Rochester was with Eastman Kodak, but my wife—who already worked there—told me Kodak did not hire people off the street. I had no choice but to try and to our surprise, with my meager background in optics, I was hired on the spot.

Bob’s first assignment was to measure the radius of curvature of long-radius test plates with an autostigmatic microscope—the forerunner of the Point Source Microscope (PSM). Finding Kodak somewhat rigid in their thinking, Bob left in 1968 to work for Itek in Lexington, Massachusetts, where he was given more freedom to pursue some of his own ideas, while working on interesting optical projects. And, once again, he crossed paths with Jim Wyant—with offices across the hall from each other.

After four years of working for Itek, government funding began to change, and I was assigned to adding tolerances to optical drawings. Without knowing how the optics were made, I did not think I could do this in a meaningful way and asked if I could spend time in the optics shop to learn how the opticians went about their business and what tools they used to measure the optics. My idea was turned down, so I left Itek to work for Frank Cooke who had an optics shop in North Brookfield, Massachusetts. There I gained experience in cam grinding of aspherics, diamond turning of metal optics and polishing of hydroscopic materials.

One of the greatest influences on Bob at Frank Cooke’s was Ray Boyd, an optical engineer who oversaw optical design and metrology. Ray had worked for a time at Harvard Observatory then moved to Southbridge, Massachusetts, to work at the American Optical Company. While at American Optical, Ray had worked briefly with Walter Siegmund, who made significant contributions to the field of fiber optics. Through this connection, Ray was able to get fiber preforms that he would draw down to a small diameter to make a point-source of light when the large end of the preform was illuminated. Ray used this source, along with an eyepiece, to measure the concentricity of the hyper-hemispherical domes that Frank was making—another one of the insights that led to the PSM.

Optical Sciences Center

Around 1976, Bob was involved with a job Frank Cooke was doing for Hughes Aircraft Company (now, Raytheon) in Tucson, Arizona.

Bob Fischer, who I had known while at Itek, was now at Hughes and he came out to Frank Cooke to do a source inspection. During our talk, he mentioned that the graduate student managing the optics shop at the Optical Sciences Center (OSC) at the University of Arizona was graduating and the department was looking for someone to run the shop. By now, Jim Wyant was at OSC so I asked Bob if it made sense to contact Jim to see if he thought I could be a possible candidate. Bob readily gave me Jim’s phone number and I called him. Not only was his answer, “yes,” but he picked me up at the airport when I flew to Tucson for an interview with OSC’s director Peter Franken.

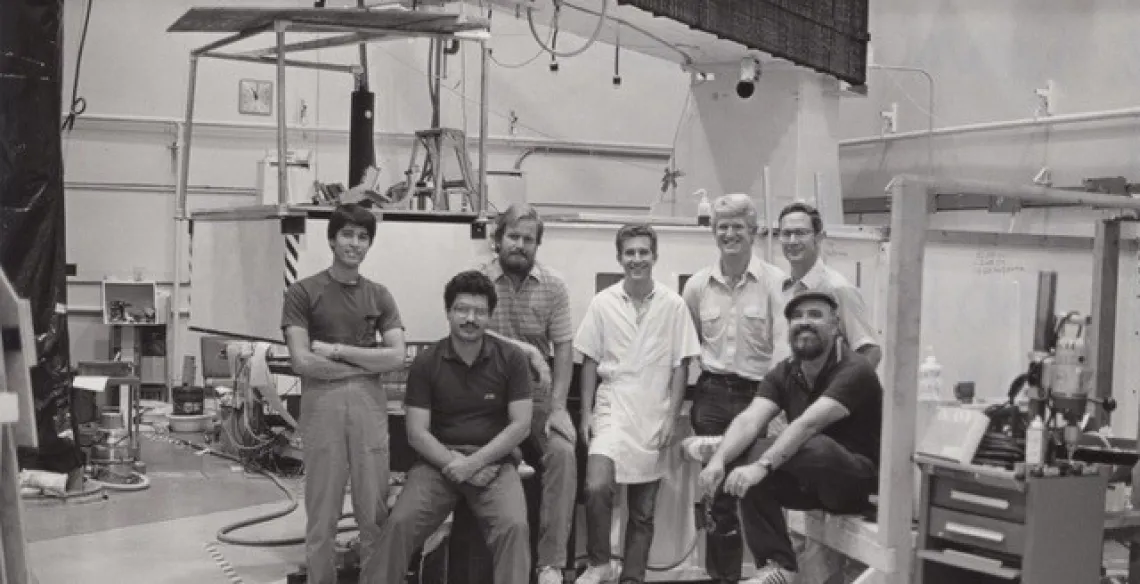

OSC Optics Shop Staff (Bob Parks, second from the right)

Bob received an offer from Peter the next day, who jokingly said the only requirement was “that he not bring shame to OSC as a result of running the shop.” The job running the shop turned out to be a perfect fit for Bob; the work had to be done in a timely manner, but he was free to accomplish the work in any way he wanted. Since Bob had run all the machines used to make optics at Frank Cooke, he could now communicate well with the opticians, and much was accomplished.

Major Projects

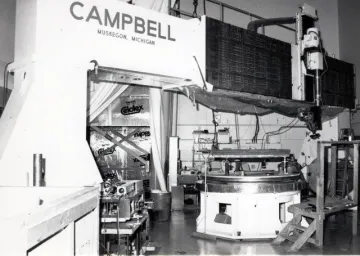

Mold for the Arecibo Radio Telescope | (From Left) Bob Parks, Dean Ketelsen, Cary Kittrell, Dave Anderson

During Bob’s tenure as manager of the optical shop, there were two major projects that significantly aided the manufacturing of large telescopes. The first was the Large Optical Generator (LOG)—a 5-meter swing, computer-numerically-controlled vertical grinder that was used as a generator for making molds for the multiple panels that went into the primary mirror of the 10-meter Sub-Millimeter Telescope—a joint project of Steward Observatory at the University of Arizona and Max Planck Institute for Radioastronomy in Bonn, Germany.

The molds for the panels were made by swinging the glass substrates back and forth under the grinding wheel while contouring in two dimensions. Once the project was successfully completed, we demonstrated that the LOG could be used for three-dimensional contouring, and we used it to make the molds for the secondary and tertiary mirrors for the Arecibo radio telescope in Puerto Rico—the one that recently collapsed and has been decommissioned.

Another tool developed in the optics shop was the swing-arm profilometer. This tool went on to be substantially perfected at the Mirror Lab, and then brought back to OSC for making measurements on aspheric optics to the same level of precision that could be done with interferometric testing.

We proved the concept of the swing-arm profilometer in the shop but never really had much occasion to use the technique. One of our opticians, Dave Anderson, was making modest-sized telescope mirrors in his garage and developed a working instrument for his own use. Later, he began working at the Mirror Lab and showed them how his swing-arm profilometer worked. The people at the Mirror Lab vastly improved the instrument and used it for measuring the mirrors they were making. Once the instrument was returned to OSC, we added a second sensor which made the swing-arm profilometer completely self-calibrating.

Professional Societies

The Parks Family at SPIE Optics & Photonics Conference 2021, San Diego

Over the years, Bob has served the optical societies OSA and SPIE in several roles, including serving on SPIE’s Board of Directors from 1989-92 and being elected a Fellow of the Society in 1985.

In 1986, at the request of then-president of OSA, Jean Bennett, Bob led the first U.S. delegation to a meeting of the International Organization for Standardization (ISO) Technical Committee 172, Optics and Optical Instruments. Over the next 10 years, he continued to head the U.S. delegation to the TC172, Sub-Committee 1 (SC1), Fundamental Optical Standards, that included work on optical drawing standards. In 1995, Bob was appointed Chairman of SC1 and, as part of his continued commitment to OSA, he wrote several monthly short articles on the work of ISO and domestic optical standards.

Additionally, Bob served two terms on the Board of Directors for the American Society for Precision Engineering (ASPE) from 1985-87 and 1989-92. He also was elected president of ASPE is 1991. In 2009, ASPE honored Bob with their Lifetime Achievement Award.

Trouble with the Hubble

Bob left the University in 1989 to start a consulting business specializing in optical fabrication and testing. Among his consulting projects was one working for the Allen Board of Investigation for the Hubble Telescope.

With the announcement of ‘first light’ from the telescope in June 1990, it was apparent to the scientists at the Space Science Institute that there was a major imaging error somewhere in the telescope and/or instrument package. (Parks, R. E., Hubble: Looking for Trouble. Optics & Photonics News, April 1991,pp. 28-29.)

As a consultant to the board, Bob created a logical explanation of the procedural errors based on measurements of the test hardware that showed how a spacing error was made in the Hubble primary mirror null lens that, in turn, led to the error in the mirror. For his contributions, Bob was awarded the NASA Public Service Medal in 1991.

Dear Bob, Thank you very much for your participation in the HST investigation. You made an enormous contribution, and I don’t see how we could have gotten it straight without you. You displayed not only rock solid optical technical knowledge, but a remarkable ability to work with people under very stressful conditions. (Dr. Lew Allen, Director, Jet Propulsion Laboratory)

Optical Perspectives Group, LLC

In 1992, Bob co-founded Optical Perspectives Group, LLC to develop and market the Point Source Microscope (PSM), a self-contained portable metrology system. Providing easy system alignment, the PSM has become an important alignment/metrology tool for many applications. To this day, Bob’s consulting experiences with Optical Perspectives provides him many opportunities to publish work on optical test methods and applications. The latest was a presentation of his newly published paper, Rapid centering of optics, at SPIE’s Optifab Exhibition on 19 October 2021.

2014 OSC Opticians and Engineers Reunion (Photo by Richard Buchroeder) | (Standing from Left) Joe Appels, Bob Crawford, Gary Poczulp, Dean Ketelsen, Ron Hilliard (Seated from Left) Bob Parks, Don Loomis, John Lytle, Bill Kuhn

Return to OSC

In 2009, at the request of Professor Jim Burge, Bob returned to OSC to help further develop two techniques that would assist with the Mirror Lab’s work on the Giant Magellan Telescope project. The first—an idea of Regents Professor Roger Angel to measure the solar reflectors he was making at the time—was what they called SCOTS, Software Compatible Optical Testing.

Roger realized that a laptop computer had all the features to be used as a stand-alone optical test device—a display on which to show a regular pattern of lines; a camera to capture a reflection of the display in the mirror you were testing; and the software to control the data gathering and process it to give a contour map of the mirror surface.

Bob worked with Jim’s student, Peng Su, to develop the technique which, by that time, was really needed at the Mirror Lab. They had run into a problem with the interferometric testing of the first GMT segment—the slope of the errors at the mirror’s edge was too steep for the interferometer’s software to unwrap and, consequently, they did not know how to proceed with polishing. After installing a computer monitor and camera at the top of the Mirror Lab test tower that looked around the other test equipment, Bob and Peng Su were able to get data of the mirror edge, enabling the team to get back on schedule again with their polishing.

The second project was based on SCOTS but called SLOTS, Scanning Long-wave Optical Testing System. Because ground glass surfaces appear smoother when viewed with long wavelength light, it is possible to get a specular reflection from a ground surface using 10-micron wavelength light; and a relatively inexpensive camera sensitive to this wavelength was just coming on the market.

While SCOTS used a monitor to display a whole set of lines at one time, SLOTS used a single heated wire and scanned it over the ground mirror. The IR camera recorded the reflection of the wire in the surface. Apparent bends in the reflected wire image indicated errors in the mirror surface. Since grinding is a much faster way to remove material from a mirror than polishing—and SLOTS could be used to guide the grinding—the Mirror Lab and OSC were able to speed up the production of off-axis aspheres and other free-form surfaces substantially.

Patents and Publications

Bob currently is the inventor or co-inventor on five issued U.S. Patents, including one on the Point Source Microscope, a product of the Optical Perspectives Group. A prolific writer, Bob is the author or co-author of over 100 publications on optical fabrication, testing and optical standards.