Date Published: December 2023

In a recent Nature Communications publication titled "UV-curable thiol-ene system for broadband infrared transparent objects," a team of scientists and faculty from the Rongguang Liang laboratory introduces an extraordinary breakthrough. They've developed a game-changing photo-curable liquid material that defies conventional limitations of infrared transparency. By ingeniously combining specific multithiols and divinyl oligomers comprising only carbon, hydrogen, and sulfur atoms, this innovative approach achieves transparency across the spectrum, spanning from visible light to mid-wave infrared (MWIR) and long-wave infrared (LWIR). This pioneering material exhibits remarkable properties, including a high refractive index, excellent thermal characteristics, and robust mechanical strength. Its versatility shines through in applications like crafting high-resolution infrared optics and constructing micro-reactors for temperature monitoring. What's truly remarkable is its UV-curable nature, offering a swift and convenient method to produce thin, infrared-transparent objects. This breakthrough not only showcases a cutting-edge material but also holds promise for a multitude of practical applications. Read more about this work and Prof. Liang's impact in this Five Minute Review.

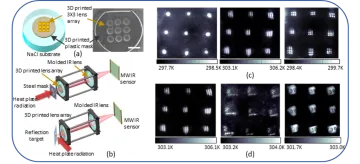

(a) Scheme of fabrication of lens array for the experiment. A 3X3 lens array was printed on a NaCl plate by two-photon polymerization using the resin prepared with tetraSH and DVO2. A polymer mask containing 3X3 holes matched to the lens array was 3D printed by a commercial digital light processing (DLP) printer and a commercial resin to block light not passing through the lens array. Scale bar: 1 mm. (b) Schemes of the imaging systems for experiments. The printed lens array and molded lens were assembled in a frame to maximize the imaging quality. Both the transmission mode (top) and reflection mode(bottom) were employed during the experiments. (c) Transmission image of steel masks with single hole (left, 5 mm diameter), vertical grille (middle, 2 mm width), and mesh grille (right, 2x2 mm for every single lattice). (d) Reflection images of USAF target (Group -2, left and middle) and a steel ruler (right) as reflection targets.

Rongguang Liang