Date Published: June 5, 2024

Researchers, led by Ron Liang, Thomas R. Brown Endowed Chair in Optical Sciences and professor of optical sciences; are making significant progress in the field of 3D printing for glass micro-optics. This work was recently published in Advanced Optical Materials, titled, "Solvent-Free Silsesquioxane Self-Welding for 3D Printing Multi-Refractive Index Glass Objects." The research presents a major advancement in the 3D printing of inorganic glass optics, featuring several key innovations:

- Development of self-welding, solvent-free PSQ: This novel material allows for the fabrication of inorganic glass objects with minimal shrinkage and high precision.

- Integration of Zirconium (Zr) moieties into PSQ: This modification enables tunable refractive indices, enhancing the adaptability of the glass for various optical applications.

- Utilization of two-photon polymerization (TPP) 3D printing: This technique enables the fabrication of micro-sized objects with feature sizes smaller than 80 nm, achieving high-resolution prints.

- Demonstration of self-welding in multi-component glass micro-optics: The self-welding capability facilitates the construction of complex structures without the need for additional binding processes.

This research marks a significant leap in optical material science and fabrication, particularly in 3D printing technologies. The introduction of an optical material with inherent self-welding properties simplifies the manufacturing process and expands the range of potential applications. These advancements hold promise for diverse applications in optics, photonics, and microfluidics.

Moving forward, with support from the NIH, the lab will receive an advanced printing system in November, which will drive further research in additive manufacturing of micro-optics and enhance 3D printing efforts for precision optical elements in biomedical optical imaging and microfluidics. This will solidify Liang's lab as a leader in the advanced design and manufacturing of micro-optics. Learn more about this work and Liang's goals in this five-minute review.

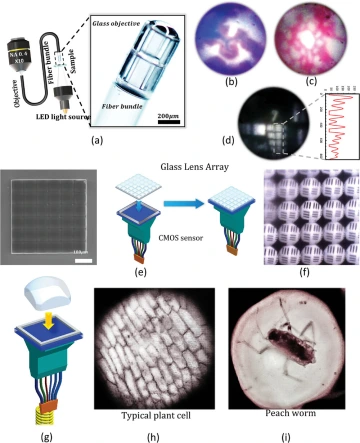

(a) The schematic diagram and microscopic image of the experimental setup for fiber-bundle imaging experiments. (b) The image of the histological slide of human fallopian tissue captured by the system is shown in (a). (c) The image of the slide of the injected rabbit lung sample. (d) The image of 1951 USAF target 7th group elements. Note that the honey cone pattern caused by fiber bundle has been removed by imaging processing using the software. (e) The SEM image of the manufactured 6X6 glass microlens array, and the scheme of the lens array on the CMOS sensor with a pixel size of 1.75 µm X 1.75 µm. (f) The image captured by the setup in (e) of a resolution target. (g) The scheme of setup is fabricated using a singular lens. (h)-(i) The images captured by the single lens mounted on a CMOS sensor of bio-samples (plant cell & peach worm).